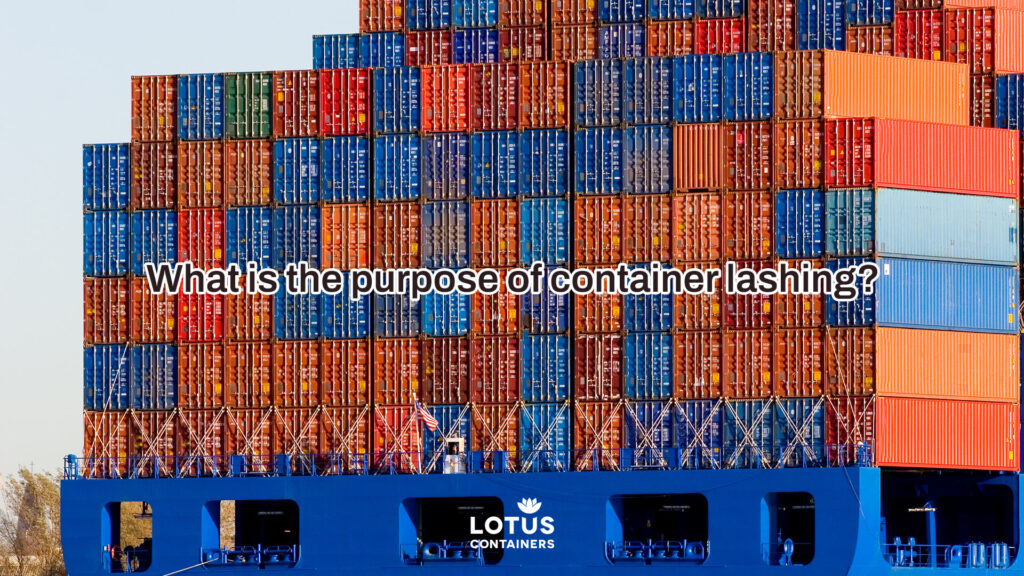

Shipping containers in the maritime industry are exposed to harsh climatic conditions and rough winds at sea. When loaded onto ships in stacks, it is crucial to properly fix them with adjacent containers, so they do not fall off due to the turbulence caused at sea. Cargo containers are huge metal boxes of different sizes that require appropriate lashing to hold the bulk load of the container and the cargo inside. Lashing helps secure the containers to their places stacked on each other for the timely delivery of enormous shipments. Container lashing is essential to save the containers from falling off or slipping and keep them intact in their position. This blog will help you learn more about how lashing helps containers onboard.

What is container lashing?

Cargo containers are conex boxes that store different types of cargo to transport them transcontinentally or internationally to their destination. While being prepared for transit, these containers are stacked one on top of the other to utilise all the available space and allow more containers to be transported in one go. The shipping containers undergo a long journey while making international shipments and therefore need to be secured to avoid any falls or tripping off the stack. It is here that container lashing becomes an essential part of transportation. Most of the international shipment is sent to the maritime industry to be transported via ships as they are a cost-effective solution for long-distance transportation. The conditions at sea may get rough and cause heavy turbulence and imbalance the containers leading them to fall off the ship. Container lashing is the process of securing containers with equipment to prevent the stacked containers from falling off the ship and maintain their balance during any turbulence at sea.

How can container cargo lashing improve maritime efficiency?

Plenty of containers topple and fall off the ship; if unnoticed, they get lost at sea. Most of the time, such incidents result from poor container lashing. For example, the containers stacked one above the other bear pressure on each other and get imbalanced during their voyage. If the turbulence increases, the containers suffer jerks and bumps and slip off each other due to the moisture and water on them. But if the containers are tied to adjacent containers and framework structures, they get support and remain intact in their position. This helps the maritime industry offer security to shippers and improves marine revenue and efficiency.

Therefore, container lashing contributes to securing the containers in their places and avoiding economic losses for the shippers and consignees due to the falling of containers off the board.

What are container lashing equipments and tools?

The process of different types of container lashing is successfully carried out using lashing equipment. Lashing of cargo in containers helps secure the different types of containers of all sizes and keeps them intact in their position. It minimises any chances of falls or tripping off during the voyage. Essential lashing equipment in the container lashing system used while loading containers onto vessels is-

- Stacking Cones– These are cones made out of metal in the shape of pyramids that help in connecting the two containers transversally. They help align the stacked containers and prevent them from shifting from their position.

- Lashing Rods– These bars connect the stacked containers to the vessel to offer extra support. They help the large stacks of containers from swaying and impacting other stacked container towers while the ship is on a voyage.

- Turnbuckles– These are hook-type structures used along with lashing rods to secure the stacked containers with the ship.

Apart from these major elements in the container lashing system, a few more resources such as ropes, nets, cables, and wires help securely anchor the container and cargo inside it to the vessel.

How does container lashing work?

Fixing containers in one place is crucial to avoid any chances of fatality, injury or severe damage to workers or cargo. Therefore, container lashing rules are crucial and must be carried out properly. The best practises of container lashing are-

- The workers must wear appropriate safety equipment before starting the lashing process.

- Depending on how many containers are loaded on a vessel, the containers can be lashed vertically, in stacks or blocks.

- Stacking cones are attached to the container before loading them onto the ship.

- Containers are stacked one above the other with the help of cranes onboard.

- After being stacked, the corner postings are tightened with the help of lash bars.

- Lashing rods fitted with turnbuckles are used to fasten the containers to the lashing bridges to provide extra support.

- The lashing rods are anchored to lashing bridges built at different heights to enable a higher container stack without any risks of the container falling off.

- Use a lash spanner to tighten the bottle screws correctly tightened to rods and bridges.

What is the purpose of container lashing

Container lashing is performed by all shipping companies in the maritime industry to ensure the security of cargo, containers, ships, and human life. It is advised by the International Maritime Organisation to inspect if the container lashings on cargo ships are done adequately following the proper process as a part of the shipping process.

- Keeps containers intact- A properly secured container helps minimise risks of shifting or slipping of containers, which may impact other containers as well.

- No falling off- When done appropriately, following all steps, lashing prevents cargo loss due to containers falling off the ship while in transit.

- Reduces damage to goods– Even if the container does not fall into the sea, the jerks it suffers due to tripping may lead to cargo damage. Therefore, lashing is essential.

- Lesser injuries and fatalities- Workers often inspect the containers onboard during the voyage to check if everything is fine. Any fall of containers from its tack can cause fatal injuries to the workers. Lashing helps in avoiding them.

Therefore, container lashing is a secure way of avoiding hazards associated with the maritime industry and carrying out a safer voyage for the cargo and seafarers.

LOTUS Containers is a premium shipping company offering shipping container solutions across the globe. We sell used and new shipping containers to suit the requirements of our clients.